Introduction

Table of Contents

Auto darkening welding helmet have revolutionized the welding industry, transforming the way welders work and ensuring their safety. If you’re a welder or have ever been around welding, you’ve likely seen these futuristic-looking helmets in action. They sport a sleek design, but more importantly, they provide critical protection for welders by automatically adjusting the level of darkness in the helmet’s lens to shield their eyes from the intense glare of welding arcs.

In this comprehensive guide, we’ll delve deep into the world of auto-darkening welding helmets, exploring everything from their fundamental purpose to their advanced features, and even offering recommendations for the best models on the market. Whether you’re an experienced welder looking to upgrade your gear or a novice trying to understand the basics, this article is your ultimate resource.

But first, let’s address the core question that often lingers in the minds of both seasoned welders and beginners: What exactly are auto-darkening welding helmets, and why are they considered a game-changer in the welding industry?

Chapter 1: Understanding Auto-Darkening Welding Helmets

1.1 Definition and Purpose

Auto-darkening welding helmets, also known as ADWHs, are a remarkable piece of safety gear designed specifically for welders. Unlike traditional welding helmets with fixed shade lenses, these helmets feature a technologically advanced lens that can automatically adjust its darkness level in response to the intensity of the welding arc.

In this article, we will delve into the essential features that make auto-darkening welding helmets indispensable tools for welders. While we’ll cover the key aspects comprehensively, it’s always a good idea to refer to industry experts and organizations for in-depth insights.

One such reputable source is the American Welding Society (AWS), a globally recognized authority in welding and related technologies. The AWS provides valuable information, standards, and resources for welders of all levels. Their guidance can be particularly helpful when it comes to understanding the latest advancements in welding safety gear, including auto-darkening helmets.

By staying informed through organizations like the AWS, you can ensure that you’re making informed decisions when choosing the right auto-darkening welding helmet for your specific needs.

The primary purpose of an auto-darkening welding helmet is to protect the welder’s eyes and face from the hazardous effects of welding, which include:

1.1.1 Intense Light and UV Radiation: Welding produces extremely bright and harmful light, including ultraviolet (UV) and infrared (IR) radiation, which can cause eye damage and skin burns if not properly shielded.

1.1.2 Arc Flash: The intense burst of light created when the welding arc initiates can lead to “arc flash” or “welder’s flash,” a painful condition similar to a sunburn affecting the eyes and surrounding areas.

Auto-darkening helmets mitigate these risks by automatically darkening the lens the moment the welding arc is struck, offering instant protection for the welder’s eyes and face. This instantaneous adjustment ensures that the welder can clearly see the workpiece and the welding arc during the welding process while staying safe from harmful radiation.

1.2 Key Features and Benefits

Auto-darkening welding helmets come with an array of features that contribute to their popularity among welders. Here are some key features and the benefits they provide:

1.2.1 Variable Shade Control: Auto-darkening helmets allow welders to adjust the darkness level of the lens to match the welding process and material. This flexibility ensures optimal visibility and protection.

1.2.2 Rapid Response Time: These helmets react within milliseconds to darken the lens when the welding arc is initiated, minimizing the risk of eye damage from accidental exposure to the intense light.

1.2.3 Sensitivity Adjustment: Sensitivity controls enable welders to fine-tune the helmet’s response to different welding processes, ensuring reliable performance in various work environments.

1.2.4 Grind Mode: Many auto-darkening helmets come with a grind mode, allowing welders to use the same helmet for grinding and welding, eliminating the need to switch between helmets.

1.2.5 Lightweight and Comfortable: Modern auto-darkening helmets are designed for comfort, often featuring lightweight materials and ergonomic headgear that reduces strain during long welding sessions.

1.2.6 Increased Productivity: With instant darkening and clear visibility, welders can work more efficiently, leading to increased productivity.

1.3 Variations in Auto-Darkening Technology

Auto-darkening welding helmets utilize advanced technology to achieve their remarkable functionality. There are three primary technologies used in auto-darkening lenses:

1.3.1 Liquid Crystal Display (LCD) Technology: These helmets feature liquid crystal cells that change opacity when voltage is applied. The LCD technology allows for precise control of darkness levels and response times.

1.3.2 Variable-Shade Technology: This technology enables the lens to switch between different shades, providing adaptability for various welding processes and environments.

1.3.3 Photovoltaic Technology: Some auto-darkening helmets are powered by solar cells, eliminating the need for batteries. These helmets harness energy from welding arcs and ambient light to power the darkening process.

Each of these technologies has its advantages, and the choice between them often depends on personal preference and the specific requirements of the welding task at hand.

Chapter 2: Top Picks – The Best Auto-Darkening Welding Helmets

Now that we have a solid understanding of what auto-darkening welding helmets are and why they are essential, let’s explore some of the top-rated models available in the market today. These helmets have been chosen based on their performance, features, and user reviews.

2.1 Miller Auto Darkening Welding Helmet

2.1.1 Model: Miller Electric Digital Elite Auto-Darkening Welding Helmet

Key Features:

- Four operating modes for versatility (weld, cut, grind, X-Mode)

- ClearLight lens technology for enhanced color and clarity

- Quick-release front cover lens holder for easy lens replacement

- Digital controls for precise adjustments

- Excellent response time for maximum protection

- Comfortable and adjustable headgear

Benefits:

- Ideal for professional welders and hobbyists

- Exceptional clarity and color perception

- Versatile for various welding and cutting applications

- Durable construction for long-lasting use

- Comfortable to wear for extended periods

2.1.2 Pros and Cons of the Miller Electric Digital Elite Helmet

Pros:

- Advanced features and modes cater to different welding needs.

- The ClearLight lens offers superior visibility and clarity.

- User-friendly digital controls for precise adjustments.

- Excellent headgear ensures comfort during long welding sessions.

- Durable construction for longevity.

Cons:

- Higher price point compared to some competitors.

- May be considered overkill for occasional or hobbyist use.

2.2 Lincoln Electric Auto-Darkening Welding Helmet

2.2.1 Model: Lincoln Electric Viking 3350 Auto-Darkening Welding Helmet

Key Features:

- Extra-large 12.5 square-inch auto-darkening lens

- Four arc sensors for reliable darkening response

- 1/1/1/1 optical clarity rating for exceptional visibility

- Variable shade settings (5-13) for versatile applications

- Grind mode for post-weld cleanup

- Lightweight and comfortable design

Benefits:

- Industry-leading optical clarity for precise work

- Large lens provides an unobstructed view of the work area

- Adjustable shade settings accommodate various welding tasks

- Durable and comfortable design for long-term use

- Grind mode eliminates the need for a separate grinding helmet

2.2.2 Pros and Cons of the Lincoln Electric Viking 3350 Helmet

Pros:

- Outstanding optical clarity and visibility.

- A large lens offers an expansive view of the welding area.

- Versatile shade settings suit a wide range of welding processes.

- Comfortable and durable design for extended use.

- Grind mode simplifies post-weld cleanup.

Cons:

- May be considered relatively expensive for beginners.

- Some users may find the helmet a bit heavy for extended use.

2.3 ESAB Auto-Darkening Welding Helmet

2.3.1 Model: ESAB Sentinel A50 Auto-Darkening Welding Helmet

Key Features:

- Crystal-clear 5.0 square-inch color touchscreen display

- Shade range from 5 to 13 with an external grind mode button

- Four arc sensors for lightning-fast switching

- True Color lens technology for a realistic view of the welding area

- Ergonomic Halo headgear for comfort and balance

- Unique, futuristic design

Benefits:

- Intuitive touchscreen display for easy adjustments.

- Wide shade range caters to various welding processes.

- Fast-switching sensors ensure instant darkening.

- True Color technology provides a natural view of the weld area.

- Comfortable and balanced headgear minimizes strain during use.

- Eye-catching and distinctive design.

2.3.2 Pros and Cons of the ESAB Sentinel A50 Helmet

Pros:

- User-friendly touchscreen display for precise control.

- Versatile shade range suits different welding applications.

- Rapid sensor response ensures quick darkening.

- True Color technology enhances the welding experience.

- Comfortable and balanced headgear minimizes discomfort.

- Striking and distinctive design.

Cons:

- Considered a premium helmet with a higher price tag.

- Some welders may find the futuristic design less traditional.

2.4 Jackson Safety Auto-Darkening Welding Helmet

2.4.1 Model: Jackson Safety W70 BH3 Auto-Darkening Welding Helmet

Key Features:

- Balder technology for superior optical clarity

- Wide shade range (9-13) with a grind mode

- Four arc sensors for quick and reliable darkening

- Lightweight and ergonomic design

- Sensitivity and delay adjustments for customization

- Solar-powered with battery backup

Benefits:

- Exceptional optical clarity enhances precision.

- Versatile shade range suits multiple welding processes.

- Reliable sensor response ensures safety.

- Lightweight and ergonomic design for comfort.

- Customizable sensitivity and delay settings.

- Solar power with battery backup for uninterrupted use.

2.4.2 Pros and Cons of the Jackson Safety W70 BH3 Helmet

Pros:

- Outstanding optical clarity for precise work.

- Versatile shade range accommodates various welding tasks.

- Reliable sensor response ensures safety.

- Lightweight and ergonomic design for comfort.

- Customizable sensitivity and delay settings.

- Solar power with battery backup for continuous operation.

Cons:

- Some welders may prefer a larger viewing area.

- The design may be considered less flashy compared to some competitors.

Chapter 3: The Battery Conundrum

3.1 Do All Auto-Darkening Welding Helmets Have Batteries?

One of the common questions that arise when considering auto-darkening welding helmets is whether they all require batteries. The answer is: not necessarily. Auto-darkening helmets can have different power sources, and not all of them rely solely on batteries. Here are the primary power sources for these helmets:

3.1.1 Battery-Powered Helmets:

Many auto-darkening welding helmets are equipped with replaceable batteries, typically of the AAA or CR2450 variety. These batteries power essential functions, such as the electronic controls and LCD screen (if applicable). Battery-powered helmets are convenient because they don’t rely on external light sources and can be used in any environment, even in low-light conditions.

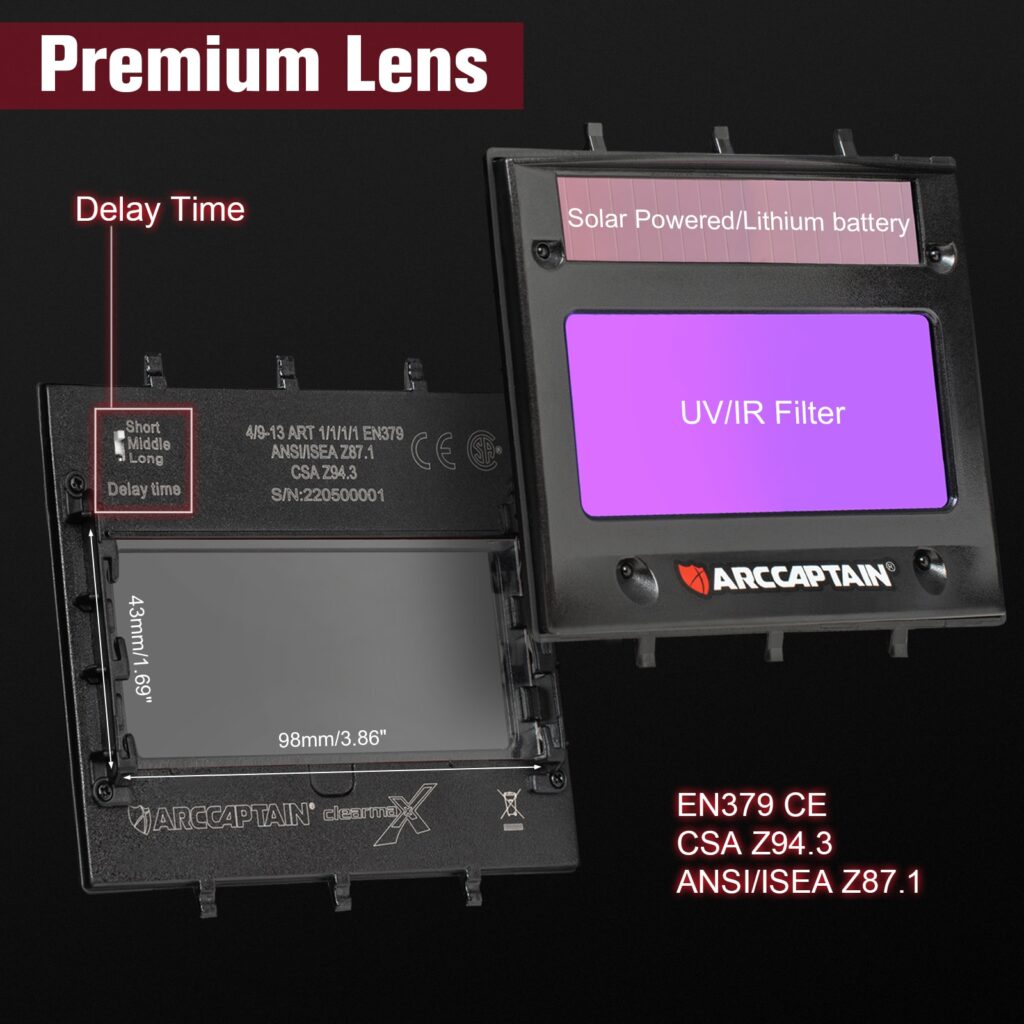

3.1.2 Solar-Powered Helmets:

Solar-powered auto-darkening helmets are designed to harness energy from welding arcs and ambient light. They often feature a solar panel on the helmet’s exterior, which charges an internal battery. This design eliminates the need for frequent battery replacements and can significantly extend the helmet’s lifespan. Solar-powered helmets are environmentally friendly and cost-effective in the long run.

3.1.3 Combination Helmets:

Some auto-darkening welding helmets combine both battery and solar power sources. These helmets provide the versatility of battery power and the energy-saving benefits of solar power. In this setup, the solar power primarily maintains the helmet’s functionality, while the battery serves as a backup power source for low-light conditions.

3.2 Battery Types and Lifespan

When it comes to battery-powered auto-darkening welding helmets, the type of battery used can impact performance and lifespan. Here are some common battery types found in these helmets:

3.2.1 AAA Batteries:

Helmets that use AAA batteries are convenient because these batteries are widely available and relatively inexpensive. However, they may have a shorter lifespan compared to other battery types, necessitating more frequent replacements.

3.2.2 CR2450 Batteries:

CR2450 batteries are coin-cell lithium batteries that provide longer battery life compared to AAA batteries. This means less frequent replacement and more extended use before needing a new battery.

3.2.3 Rechargeable Batteries:

Some auto-darkening welding helmets come with rechargeable battery options. These helmets often include a USB charging port for easy recharging. Rechargeable batteries can be a cost-effective and environmentally friendly choice in the long term.

3.2.4 Battery Lifespan:

The lifespan of batteries in auto-darkening welding helmets varies depending on factors such as helmet usage, sensitivity settings, and the type of battery. On average, users can expect battery-powered helmets to last several hundred hours of welding before requiring a battery replacement. Solar-powered helmets, on the other hand, can last significantly longer due to their dual power source.

Chapter 4: Are All Auto-Darkening Welding Helmets Created Equal?

Auto-darkening welding helmets offer a wide range of features and capabilities, but not all helmets are created equal. When choosing the right helmet for your needs, it’s essential to consider various factors that can impact performance, comfort, and overall user satisfaction. Here’s how helmets can differ from one another:

4.1 Optical Clarity and Viewing Area

One of the critical factors that differentiate auto-darkening welding helmets is the optical clarity of their lenses and the size of the viewing area. Optical clarity is rated using a system where the higher the rating, the better the clarity. A typical optical clarity rating for auto-darkening welding helmets is 1/1/1/1, which represents four categories:

- 1.1 Optical class: This indicates the helmet’s ability to provide a clear and distortion-free view of the welding area.

- 1.1 Light diffusion: This category evaluates how uniformly the lens darkens across its surface, ensuring consistent protection.

- 1.1 Light scattering: A low score in this category means the lens minimizes scattered light effectively, reducing glare.

- 1.1 Angle dependence: This category assesses how consistent the lens’s shading is from different viewing angles.

Helmets with a 1/1/1/1 rating offer exceptional optical clarity, making them suitable for precision welding tasks. When it comes to the viewing area, a larger window provides a more expansive view of the workpiece and the welding arc. Welders often prefer helmets with a larger viewing area as it enhances visibility and allows them to work with greater accuracy.

4.2 Sensitivity and Delay Adjustments

Auto-darkening welding helmets come with sensitivity and delay adjustments that allow welders to fine-tune the helmet’s response to different welding processes and conditions. Here’s how these adjustments work:

4.2.1 Sensitivity Adjustment:

The sensitivity control determines how sensitive the helmet is to the welding arc’s brightness. By adjusting sensitivity, welders can customize the helmet’s response to their specific welding task. Higher sensitivity settings make the helmet darken more quickly in response to lower-intensity arcs, while lower sensitivity settings are suitable for high-intensity welding.

4.2.2 Delay Adjustment:

The delay control determines how long the lens stays dark after the welding arc is extinguished. This feature prevents the lens from switching back to the light state too quickly, protecting the welder from residual glare and potential eye strain. Welders can adjust the delay time to suit their preferences and working conditions.

Having the flexibility to customize sensitivity and delay settings is especially valuable because it ensures that the helmet responds optimally in various welding scenarios. Welders can adapt the helmet to their specific needs, whether they’re working on intricate TIG welding or heavy-duty MIG welding.

4.3 Grind Mode

Grind mode is a feature found in many auto-darkening welding helmets that eliminates the need for a separate grinding helmet. In grind mode, the helmet’s lens remains in a light state, allowing the welder to see clearly while grinding or performing other non-welding tasks.

The convenience of having a grind mode can significantly improve workflow efficiency, as welders can seamlessly switch between welding and grinding without the hassle of changing helmets. This feature not only saves time but also reduces the number of equipment pieces a welder needs to carry.

4.4 Comfort and Ergonomics

The comfort and ergonomics of an auto-darkening welding helmet are crucial for welders who spend extended periods wearing their gear. Helmets with well-designed headgear, padding, and adjustable straps provide a comfortable fit that reduces strain and discomfort.

Ergonomically designed helmets distribute the weight evenly across the head, minimizing pressure points and allowing welders to concentrate on their work without distractions. Some helmets even feature moisture-wicking materials to keep sweat at bay and ensure a comfortable, dry experience.

4.5 Durability and Construction

Durability is a vital consideration, especially for welders who work in challenging environments. Helmets with robust construction and materials can withstand the rigors of welding, including exposure to heat, sparks, and debris. Look for helmets with high-impact resistance and flame-retardant materials.

Additionally, some helmets come with replaceable parts, such as outer lens covers and headgear, making maintenance and longevity more manageable. A durable helmet not only ensures safety but also represents a wise investment that will last for years.

4.6 Brand Reputation and Warranty

When selecting an auto-darkening welding helmet, it’s advisable to consider the reputation of the brand and the warranty provided. Established brands with a history of producing quality welding gear are more likely to offer reliable and durable helmets.

Warranty coverage is another critical factor. A solid warranty can provide peace of mind and assurance that the manufacturer stands behind its product. Be sure to read and understand the warranty terms, including coverage duration and any conditions that may apply.

Chapter 5: The Lens Matters: Who Makes the Best Auto-Darkening Welding Lens?

The lens of an auto-darkening welding helmet is at the heart of its functionality, determining the clarity, responsiveness, and overall performance of the helmet. When it comes to the quality of the lens, some manufacturers have gained a reputation for producing outstanding lenses that enhance the welding experience. Let’s explore a few of the key players in the world of auto-darkening welding lens technology:

5.1 3M Speedglas

Speedglas 9100XXi Auto-Darkening Lens:

3M’s Speedglas brand is synonymous with high-quality auto-darkening lenses. The Speedglas 9100XXi lens offers impressive optical clarity, excellent color recognition, and a swift darkening response time. Welders who prioritize precision and visibility often turn to Speedglas for their welding lens needs.

Key Features of the Speedglas 9100XXi Lens:

- Optical clarity rating of 1/1/1/1 for exceptional clarity.

- True-View technology provides a realistic view of the welding area.

- Rapid 1/10,000-second darkening response time.

- Comfort mode for reduced eye strain during extended welding sessions.

- Shades 5, 8, 9-13 to accommodate various welding processes.

5.2 Lincoln Electric

Lincoln Electric Viking 4C Lens:

Lincoln Electric’s Viking series of auto-darkening lenses are known for their exceptional clarity and optical performance. The Viking 4C lens, in particular, is highly regarded for its ability to provide welders with a clear, true-color view of the welding area.

Key Features of the Viking 4C Lens:

- 4C lens technology for optimal color and clarity.

- Enhanced visibility of the weld puddle and workpiece.

- Rapid auto-darkening response with minimal distortion.

- Available in various Viking series helmets for versatile use.

5.3 Miller Electric

Miller Electric ClearLight Lens:

Miller Electric is another reputable brand that offers high-quality auto-darkening lenses. The ClearLight lens technology is a standout feature in Miller Electric helmets, providing welders with superior visibility and color perception.

Key Features of the ClearLight Lens:

- ClearLight lens technology for enhanced color and clarity.

- Crisp and vivid view of the welding area.

- Rapid auto-darkening response time.

- Available in Miller Electric’s Digital Elite and Digital Infinity helmets.

5.4 ESAB

ESAB’s ADF Lens:

ESAB, a prominent name in the welding industry, produces auto-darkening lenses with advanced features and performance. Their ADF (Auto-Darkening Filter) lenses are engineered to deliver clear and precise vision during welding tasks.

Key Features of ESAB’s ADF Lens:

- Exceptional optical clarity for precision welding.

- Multiple shade settings to accommodate various processes.

- Sensitivity and delay adjustments for customization.

- True Color technology for a realistic view of the weld area.

5.5 Jackson Safety

Balder Technology:

Jackson Safety’s Balder technology is known for its optical excellence. Balder lenses offer welders a clear and unobstructed view of the welding area, enhancing accuracy and reducing eye strain.

Key Features of Jackson Safety’s Balder Lens:

- High optical clarity for precise work.

- Wide shade range with grind mode for versatility.

- Rapid auto-darkening response time.

- Lightweight and comfortable design for extended use.

Each of these lens technologies has its unique strengths and advantages, catering to different welder preferences and requirements. The choice of the best auto-darkening welding lens ultimately depends on individual needs and the specific welding tasks at hand.

Chapter 6: Assessing the Worth of Auto-Darkening Welding Helmets

Auto-darkening welding helmets undoubtedly offer a host of benefits, but are they truly worth the investment? This chapter explores the cost-effectiveness, safety advantages, and productivity gains associated with these helmets.

6.1 Cost vs. Value: Are They Worth the Investment?

Auto-darkening welding helmets are often priced higher than traditional fixed-shade helmets. This price difference can lead some welders to question whether the investment is justified. To assess the worth of these helmets, consider the following factors:

6.1.1 Safety and Health Benefits:

The primary purpose of an auto-darkening welding helmet is to protect the welder’s eyes and face from the harmful effects of welding, including intense light and harmful radiation. By preventing eye injuries and conditions like welder’s flash, these helmets safeguard a welder’s long-term health. In this regard, the cost of an auto-darkening helmet is a small price to pay for injury prevention.

6.1.2 Productivity Gains:

Auto-darkening helmets contribute to increased productivity in several ways. The rapid darkening response allows welders to work more efficiently, reducing the time spent waiting for the helmet to adjust. Additionally, the ability to switch between welding and grinding modes without changing helmets streamlines workflow and saves valuable time.

6.1.3 Versatility and Convenience:

Many auto-darkening helmets come with versatile features like variable shade control, sensitivity adjustments, and grind mode. This versatility reduces the need for multiple helmets and enhances convenience. Welders can use a single helmet for various welding processes and tasks, simplifying their equipment requirements.

6.1.4 Longevity and Durability:

Auto-darkening helmets, particularly those from reputable brands, tend to be durable and built to withstand the rigors of welding. Their longevity means fewer replacements over time, further justifying the initial investment.

In summary, while auto-darkening welding helmets may have a higher upfront cost, their safety advantages, productivity gains, versatility, and durability make them a worthwhile investment for both professional welders and hobbyists.

6.2 Are Auto-Darkening Helmets Worth It?

Welders often wonder if auto-darkening helmets are worth the expense, especially when they may have been using traditional fixed-shade helmets for years. To address this question, let’s explore some of the key benefits that make auto-darkening helmets a valuable addition to any welding arsenal:

6.2.1 Enhanced Safety:

The most significant advantage of auto-darkening welding helmets is the level of safety they provide. By instantly adjusting to the welding arc’s brightness, these helmets protect the welder’s eyes from harmful UV and IR radiation. This instantaneous darkening response significantly reduces the risk of eye injuries and conditions like welder’s flash.

6.2.2 Improved Productivity:

Auto-darkening helmets contribute to improved productivity in several ways. The rapid darkening response eliminates the need for welders to lift their helmets repeatedly to check their work, reducing interruptions and downtime. Additionally, the ability to switch to grind mode without changing helmets streamlines tasks and increases efficiency.

6.2.3 Versatility:

Many auto-darkening helmets are equipped with versatile features, such as variable shade control, sensitivity adjustments, and grind mode. This versatility allows welders to use a single helmet for a wide range of welding processes and applications, eliminating the need for multiple helmets and simplifying their equipment.

6.2.4 Comfort and Convenience:

Auto-darkening helmets are designed for comfort and convenience. They often feature ergonomic headgear, adjustable straps, and moisture-wicking materials to reduce strain during long welding sessions. The convenience of not having to lift and lower the helmet repeatedly adds to the overall comfort and efficiency.

6.2.5 Long-Term Cost Savings:

While auto-darkening helmets may have a higher initial cost compared to traditional helmets, their durability and longevity mean fewer replacements over time. Additionally, helmets with solar power sources can reduce ongoing battery expenses.

In light of these advantages, auto-darkening welding helmets are indeed worth the investment for welders looking to prioritize safety, productivity, and comfort in their work.

6.3 Can an Auto-Darkening Welding Helmet Fail?

Auto-darkening welding helmets are designed to provide reliable and consistent performance. However, like any piece of equipment, they can encounter issues and malfunctions. Let’s explore some common issues and potential reasons behind helmet failures:

6.3.1 Delayed or Sluggish Darkening:

In some cases, an auto-darkening helmet may experience delayed or sluggish darkening, meaning the lens doesn’t respond as quickly as it should. This issue can occur due to:

- Low Battery: If the helmet is battery-powered, a low or failing battery can lead to slow darkening. Regularly replace the batteries to ensure optimal performance.

- Sensitivity Settings: Incorrect sensitivity settings can cause delayed darkening. Adjust the sensitivity to match the welding environment and process.

- Damaged Sensors: Sensors on the helmet can become damaged or obscured, affecting their response time. Regularly inspect and clean the sensors to maintain their functionality.

6.3.2 Inconsistent Darkening:

Inconsistencies in darkening can be frustrating for welders. These inconsistencies may result from:

- Low Light Conditions: In environments with insufficient lighting, solar-powered helmets may struggle to charge their internal batteries, leading to inconsistent darkening. Consider using battery-powered helmets in low-light settings.

- Lack of Calibration: Some auto-darkening helmets require occasional calibration to ensure consistent performance. Refer to the manufacturer’s instructions for calibration procedures.

- Dirty or Damaged Lens: A dirty or damaged lens can affect the helmet’s ability to darken uniformly. Regularly clean and inspect the lens for any issues.

6.3.3 Failure to Return to Light State:

After the welding arc is extinguished, the helmet should promptly return to its light state. Failure to do so can be due to:

- Delayed Delay Settings: If the delay setting is too long, the helmet will remain darkened for an extended period after welding. Adjust the delay setting to a shorter duration.

- Sensor Issues: Sensor problems, such as damaged or blocked sensors, can prevent the helmet from recognizing that the welding arc has ceased. Inspect and clean the sensors as needed.

6.3.4 Lens Scratches or Damage:

The lens of an auto-darkening helmet is a critical component, and scratches or damage can impair visibility. To prevent this issue, avoid exposing the helmet to abrasive materials, and replace the lens if it becomes scratched or damaged.

In summary, while auto-darkening welding helmets are generally reliable, they can encounter issues related to batteries, sensitivity settings, sensors, calibration, and lens damage. Regular maintenance, correct usage, and adherence to manufacturer guidelines can help prevent and address these problems.

Chapter 7: Conclusion

Auto-darkening welding helmets have revolutionized the welding industry, offering welders an unmatched combination of safety, comfort, and efficiency. These helmets have evolved over the years, incorporating advanced technologies and features that cater to the diverse needs of welders across various industries.

In this comprehensive guide, we’ve explored the fundamental aspects of auto-darkening welding helmets, including their definition, purpose, key features, and the different technologies they employ. We’ve also provided recommendations for some of the top-rated auto-darkening welding helmets on the market, highlighting their key features and benefits.

Additionally, we’ve addressed essential topics such as the power sources of auto-darkening helmets, the importance of lens quality, and the factors that differentiate helmets from one another. We’ve also discussed the cost-effectiveness of these helmets, their safety advantages, and the potential for increased productivity in welding operations.

Ultimately, the decision to invest in an auto-darkening welding helmet should be driven by the recognition of the numerous benefits they offer, including enhanced safety, improved productivity, and long-term cost savings. These helmets represent a valuable tool for welders of all levels of experience, from hobbyists to seasoned professionals.

As technology continues to advance, auto-darkening welding helmets are likely to evolve further, incorporating even more innovative features to meet the ever-changing demands of the welding industry. Staying informed about the latest developments and choosing a reputable brand will ensure that welders continue to enjoy the advantages of this transformative safety gear.

In conclusion, auto-darkening welding helmets are not merely tools; they are investments in safety, efficiency, and the future of welding. As the welding industry forges ahead, so too will the advancements in auto-darkening helmet technology, ensuring that welders can work with confidence, precision, and protection.

Remember, your choice of an auto-darkening welding helmet can significantly impact your welding experience, so select one that aligns with your specific needs, preferences, and the demands of your welding projects. Whether you’re welding for a living or pursuing it as a hobby, the right helmet can make all the difference in the world of welding.